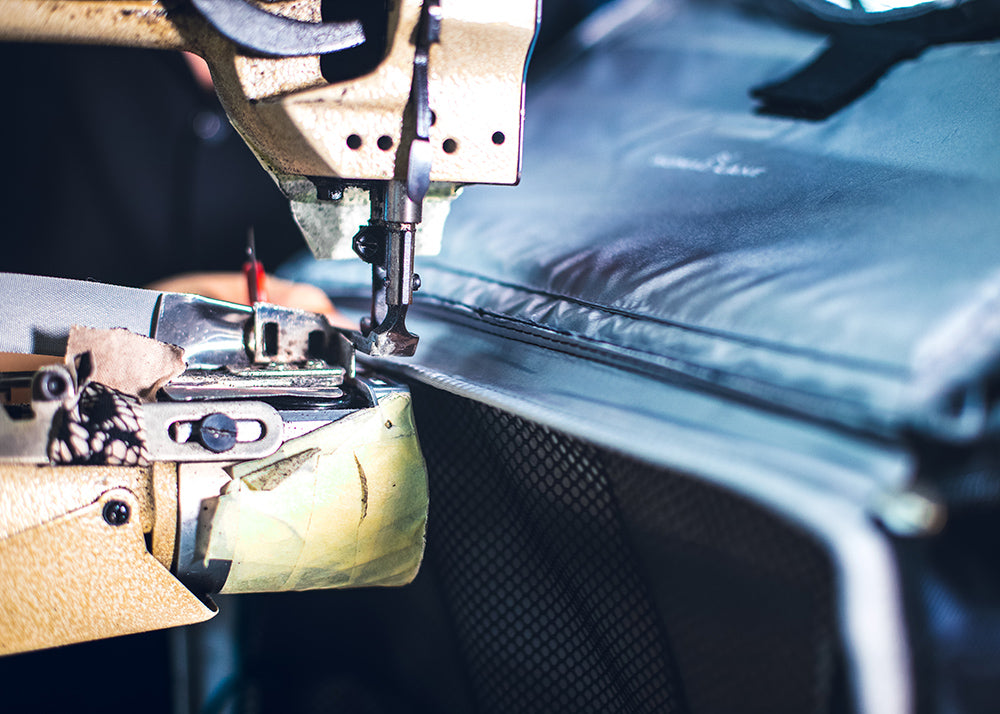

Expert craftsmanship, perfected over decades.

In 2019, we relocated production to Vietnam, choosing a factory with a rich history of crafting high-performance bags. After months of research, we found a partner trusted by some of the world's top brands, with expertise dating back to the 1970s.

Ethical Manufacturing

As part of our commitment to responsible production, we select partners who uphold high ethical standards for their workforce. We prioritize family-run factories with a focus on skilled labor, ensuring that every product is made with care and integrity.

Our manufacturing partners abide by set production hours to ensure employee safety and security.

We visit our partners often and take the time to build strong personal relationships with the owners. We go out to dinner together, make jokes and talk about the ways we can grow together.

Ethical Manufacturing

As part of our selection process, we ensure that the partners we choose abide by strong ethical practices as it relates to their workforce. We specifically look for family-run factories that focus on higher-end skilled labor because we consider them our trusted manufacturing partners.